Paper & Card Packaging Solutions for Books & Printed Media

More and more publishers, printers and bookshops are turning to paper and cardboard wrapping to meet environmental goals and improve their impact on the planet. Talk to us to find your solution!

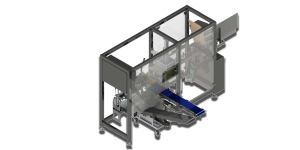

- Varo E-com Packer

- Buhrs - Poly & Paper Wrapping

The E-com Packer 900 / 1800: E-Commerce wrapping like never before

– Can pack up to 900/1800 ready-to-ship packages per hour

– A perfect match for both manual & automated storage systems

– Can handle both singular or multiple items without changing setup or stopping

– Option of 2 cover sizes

– Can apply two labels

– Environmentally friendly, plastic free solution that is fully recyclable

Fold2Protect:

Inner box that is used to secure multiple items and provide additional protection.

An optional tool for extra efficiency on the 900 or 1800 packer.

E-com packer 900:

Packing up to 900 ready-to-ship packages / hour on a small footprint

E-com packer 1800:

E-com packer 1800:

Packing up to 1800 ready-to-ship packages / hour on an even smaller proportionate footprint

Enquire now:

Buhrs 3000

The Buhrs 3000 Compact Poly & Paper Wr?apping System is being hailed as the new standard in performance and design in this particular product sector. The system has a smaller footprint and is lowered for more ergonomic loading of the feeders. Together with the well-known Buhrs quality and reliability this results in a high performance system that produces a high quality wrapped product.

The new Buhrs 3000 Compact Poly & Paper Wrapping System is equipped with Servo-feeders which have a standard selective function. The Servo-feeders are quickly interchangeable from the left, to the right, or an in-line position on the gathering section.

The Buhrs 3000 Compact offers the unique combination of being able to run with both poly and paper on one system. Depending on the job requirements, changeovers only take between 10-30 minutes to perform.

Paper wrapping offers users the opportunity of making your own personalised envelope independent of the size. This way you can be more creative in making a unique DM product. It also saves storage and handling costs with envelopes.

Buhrs 4000

This innovative, high quality poly and paper wrapping system is not just more flexible and safer, it is also characterised by its reduced set-up and maintenance times. As a result of this the system offers more productivity than any other system currently available. The Buhrs 4000: offering the ultimate design to help you make more money in the mailing industry.

Owing to the modularity of the Buhrs 4000, the system can be configured ideally for co-mailing. It has a low gathering section, automatic feeder synchronisation and individually controlled feeders via the new Buhrs System Controller.

Features & Benefits

- The mobile feeders are interchangeable between systems

- Feeder type, position & orientation can be changed in less than 2 minutes

- Opener position can be changed in less than 2 minutes

- Simple switch from paper to poly wrapping within 20 minutes

- Modularity for easy future system expansion

- Easy integration with equipment both upstream and downstream

Buhrs 5000

The Buhrs 5000 Paper Wrapping System is the standard in performance and design. Buhrs continues with its well-known quality and reliability, resulting in a high performance system that produces a high quality wrapped product.

Paper wrapping offers you the opportunity of making your own personalised envelopes independent of the size. This way you can be more creative in making a unique Direct Mail product. It also saves on the storage and handling costs of traditional envelopes.

The Buhrs 5000 System sets the world standard in paper wrapping, and this “Enveloper” creates an “envelope-like” paper wrap! Easy-opening self-mailer perforations and tightly closed flaps ensure easier postal sorting. The new cutting and gluing technology, together with the patented Product Positioning Unit© (PPU), creates the shortest, sharpest and most rigid edges on the market!

Features:

- Shuttle and rotary feeders to accommodate 30.000 products per hour

- Patented Product Positioning Unit (PPU) for accurate product placement and shortened wrapping length, resulting in lower paper cost

- Advanced gluing technology for high quality tightly closed wraps and lower cost

- New rotary cutting technology for high speed wrapping

- Use of pre-printed or white paper

- 50” roll un-winder including lifting device

Buhrs 7000

In the development of the Buhrs 7000 Poly and Paper wrapping system, Buhrs has combined flexibility with high net output in an ergonomic system.

With the Buhrs 7000 it is not necessary to stop the system between two different jobs, thereby increasing productivity enormously! Three main features make this possible. The mobile feeders are synchronized automatically (AFS) with the gathering chain of the system and are engaged automatically based on information from the Buhrs Data Controller (BDC). By measuring the length of the product just before the wrapping section, the Automatic Wrapping Set-up (AWS) function enables the wrapping unit to automatically set itself and adjust the seal position on the fly when necessary. It is, of course, possible to use Poly wrapping in combination with BuhrsWrap, which guarantees tightly wrapped products without any overlap.

The Buhrs 7000 offers a max speed of 25.000 wraps / hour.